|

There's more on Page Two In 2001, Miles Kingsbury's interest in fast bikes was re-sparked, and he came up with a new design, which was built very quickly, first appearing at a BHPC race at Castle Coome that June. Eventually called the 'little black number', for want of a better name, it was raced with some success by Steve 'Slash' Slade at the World Champs in Brighton that summer, until a high speed crash on the technical criterium circuit wrote it off. Miles had taken a different approach with this machine. The rider sat very upright, hunched forward, instead of being in a more recumbent position. The theory being that although it gives away a little in frontal area, the complete bike ends up very short, thus is more likely to retain laminar flow for a greater percentage of it's length, and has a smaller surface area, so less skin friction drag. Plus the rider is effectively in the same position as being tucked over on a road bike, so it should be good for utilising more similar muscles. The little black number used two 406mm wheels, with a Rolhoff hub at the back. It was a monocoque body, coming up to the shoulders, with a wrap-around screen completing the top of the bike. Over the winter, Miles started working on the next iteration of the bike, intended to be a record breaking machine rather than a circuit racer. And for this he needed a motor - enter me when I came back from Japan. Firstly Miles built a rig so that we could accurately assess just how small a space I could be fitted into, then with these dimensions we went back and spent a few weeks tweaking the shape until we were both happy with it. In order to make the foot box, and thus the nose of the bike, as small as possible, we designed a custom bottom bracket and crankset. This takes the Q-factor down to less than 50mm, with 155mm cranks. For the sake of efficiency and making it easier to fit everything in, it was decided to go to front wheel drive. Miles came up with a very simple intermediate gear change - the chain is held in line just off the centre of the bike, whilst the sprockets move laterally underneath it to change gear. The final drive is then down the left hand side, to one of John Kingsbury's narrow sprag clutched drum braked hubs.  ... ... So having everything designed, it was time to start making the plug. The previous bike had sections cut from foam and sanded down. This works, but is tedious and not as accurate as it needs to be. This time the sections were laser cut from 12mm and 6mm MDF. When glued together this gives an accurate 3D shape, and the gaps between the steps can just be filled and sanded to get a smooth finish.

Some of the pieces before assembly.

Applying epoxy to the stack of sections to form the plug for the top of the bike.

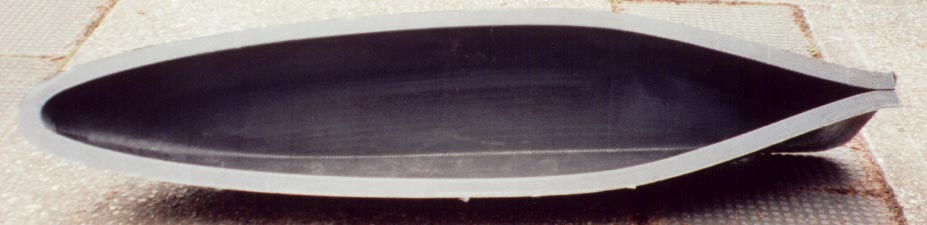

The inside view of each half of the plug - it was important

The bottom plug part filled.

Miles hard at work filling and sanding the top half of the plug.

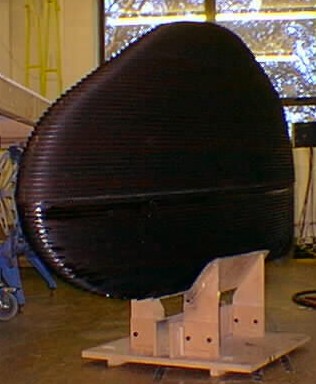

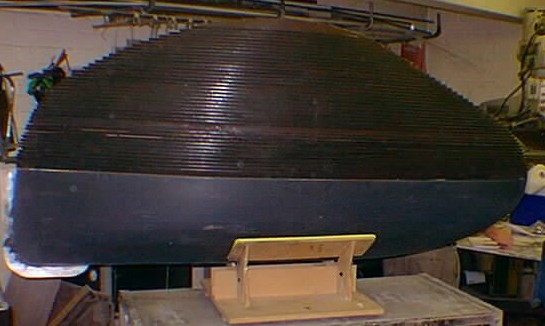

Laying up the mould.  The finished mould - nicely shows the

The finished mould - nicely shows theshape at the widest point of the bike. That's as far as we have got so far, and only six weeks to go until the hour attempt at Leystad..... Still, we will crack on and hopefully get it done in time. Watch this space for updates....... (and let us know of any good name suggestions!) There's more on Page Two |